Cashew (Anacardium occidentale) is a tree nut of growing importance in the global trade of horticulture produce. Of late, many issues have cropped up and problems have surfaced on dealing with the harvesting and post harvesting stages and further treatment in the commercial value chain.

The ratio of kernels to raw cashews is 1: 4 or below, depending on various factors that reduce yield. As it is a very expensive product, processing of cashew kernels must result in least possible destruction or damage or depreciation.

Technology has not been a driver in cashew processing and the record of failures is higher than successes over a period of time. The conflict has been between the conventional processes and the newer developments.

The evolution of cashew processing followed the course of demand. The higher demand for kernels led to the linear expansion of cashew processing, where the availability of labour was abundant. The increase in the economic cost of labour led to the concept of division of labour and evolution of the small version of the cutting machine.

The history of mechanization of cashew is since late 1950s. The advent of mechanization began as supply of equipment trade by UK, Japan and Italy. Probably other nations chipped into help the producers and consumers. Mechanization took root in Brazil and evolved, but the industry could not deliver the volumes required for world markets from their own production.

Non-availability of labour led to the innovation, which automated a part of the shelling cycle. Peeling was the most laborious part and machines were developed to remove the outer peel to the extent of 70 to 80 percent. Grading by hand evolved to small graders, which automated the process slightly to the optically sorted grades, almost simulating hand grading for sizing purposes.

The Brazilian industry got protection from increases in global raw cashew prices, which indirectly gave compensation to some of the destructive aspects of mechanization on the process and the product.

A precondition for good preservation of raw cashew is ideal to perfect sun drying to bring the equilibrium in moisture content. A fully well dried raw cashew has slightly below 9 percent moisture content. The biochemical actions turn for the worse if raw cashews are not well dried. This causes irreversible destruction and hence universal education of producer and traders is essential for making them aware of the value lost when raw cashews are not dried well. The pre-requisite is to complete the post-harvest. Drying process and process raw cashew fit for any type of manufacture.

In Africa, a combination of state policy and practices, control and regulations and market practices globally contributed to the installation and failure of mechanised practices. It ran the cashew economy to the ground and revived with market practices and resulted in the massive growth globally when market prices generated market driven policy and practices which we see today. The challenge for cashew is that the means of producing kernels and technology for production needs to be defined.

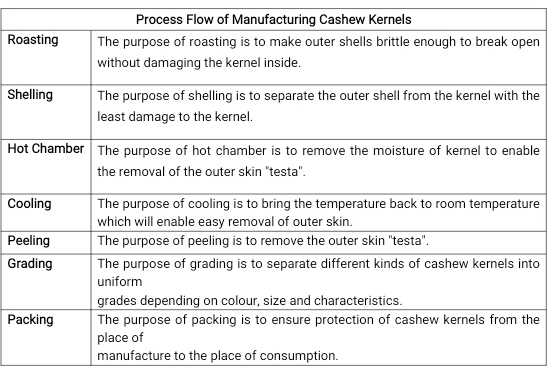

The cashew kernel extraction follows the processes of proper post-harvest care, further processing of raw cashews, conditioning of raw cashews and then roasting, shelling, oven treatments, conditioning of heated shelled kernels, peeling, sorting, elimination of testa and non-conforming degraded kernels and final grading as per commercial standards.

The Raw Cashew Is A Tough Nut To Crack. The Following Table Reveals The Process:

The peculiarity of raw cashews is that it cannot be compared to other nuts or agricultural processes. The evolution of processes to develop the kernels have been ad hoc and handed over as skills and sub processes to suit manufacture and delivery of kernels. Cashew manufacture requires a systemic study of all processes and sub processes and this need to be in situ in factories. It would be a huge challenge to have a central laboratory and development centre for cashew. Study and research of cashew manufacture is to be preceded by intense studies of the raw cashew for physical, chemical, biological, microbiology, biochemistry and water activity characteristics and behavior under different conditions and parameters.

Thus, it is clearly a case for partly manual and partly mechanical process for extracting the full or potential value of a raw cashew. The raw cashew nut is the only tree with a hard shell which has a phenolic substance. The acid which the shell can release in process and how the shell can be separated without any contamination has been satisfactorily done with manual or partly manual and mechanical processes.

Optical sorters with RBG technology evolved over sensors, which could sort to requirement. In all, the requirement of 60 employees per metric tonne produced got reduced to 10 employees in this year. The industry now comprises of a large number of heterogeneous processes.

Cashew has also a kidney shape with an indent. The other characteristic or shape issue is that it has length, width and depth which vary. The thickness of the shells varies not just from nut to nut but within a single nut at the points where the shelling would take place. Any shelling that happens has to be at a particular point with a shape that has half a kidney characteristic with a sharp centre.

This leads to issues when the nut slips and various types of damages can occur if this is done devoid of skill and when done mechanically there is no uniformity. Without shelling no further activity happens. This brings to us the sensitivity of parts of raw cashews when exposed to the process.

Cashew manufacture involves heat transfer in multiple stages that can be applied, which are critical for extraction from the outer shell and further for the gentle removal of inner testa. Cashew kernels are covered by an inedible outer skin with a predominant component of tannin.

The intricate processes for cashew kernels extraction once simple in the manual process has led to a series of complication when there are automated or mechanical processes. In mechanised processes the prerequisites go higher than in the manual process and the output or yields have qualitative, quantitative impacts as well as it alters the characteristics in a significant way that can affect the final product or the way consumer requires it.

Packaging is special to cashew due to its delicate nature. Cashew kernels have another characteristic compared to other tree nuts. It is “meaty” and has good doses of fat and carbohydrates. This requires cashew kernels to be preserved well. Cashew requires an “inert” atmosphere which requires it to have specialised packaging.

It is therefore desirable that cashew conversion is subject to severe tests after a series of observations. The objective is to magnify the value from each gram of raw cashew.

Cashew as a tree produce will defy uniformity. It is a regrettable fact that there is no established or recognised industrial research on cashew manufacture. The nature and volume of the industry now requires it to be a national or international effort, preferably backed by United Nations or an internationally recognised and backed agency.

Cashew manufacture and technology anywhere in the world will be standardized and a success only on the following criteria when set into a pre-requisite programme:

Complete and thorough post-harvest drying of raw cashews practices by producers and traders or intermediaries e.g. cooperatives and handlers

Protocols for storing and transportation of raw material that is raw cashew

Complete understanding of biochemistry in process once raw cashews are submitted to process

Suppliers and customers of cashew kernels understanding the cashew value chain

Participation of the entire value chain as stakeholders in the study, research and development

Any process technology will have to completely be the result of in depth study of the material. It is time for a World Conference on Science and Technology on cashew to establish thoroughly, the agenda and priorities for industrial research, to consolidate and explore new frontiers for cashew.